About Us

Hong Kong JMC Technology Co., Ltd.

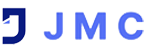

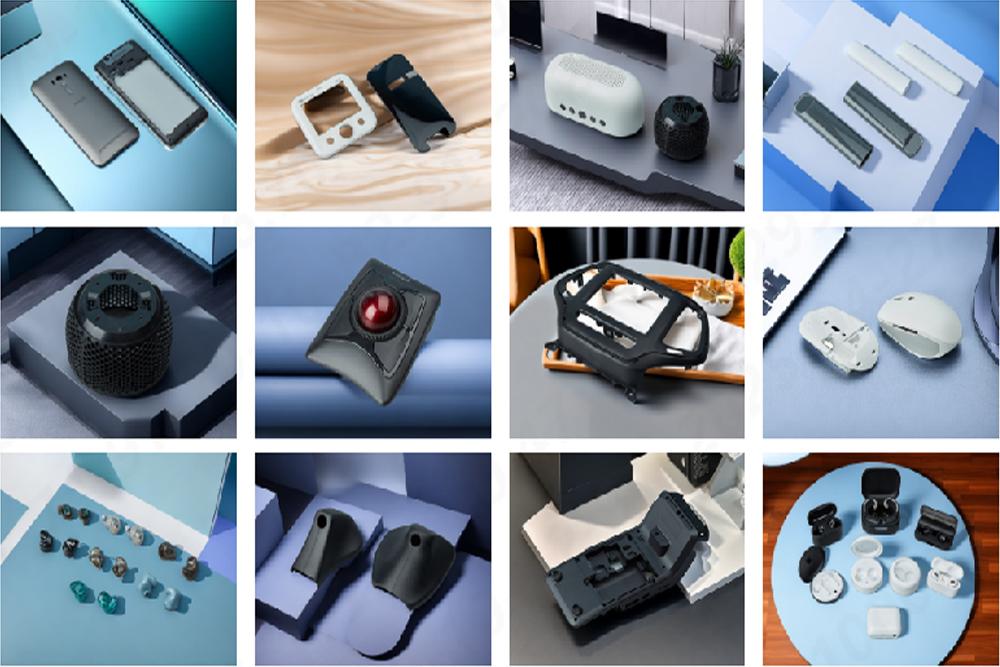

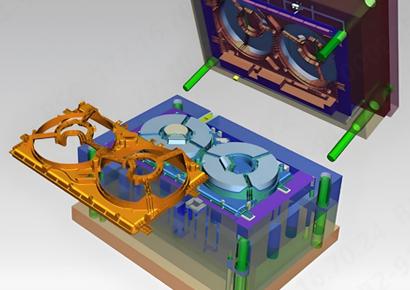

JMC is a company that integrates plastic mold making, mechanical processing, and Fresnel lens design and production.

In terms of plastic mold making, JMC is a manufacturer with 17 years of dedication to high-precision plastic mold processing and customization for Apple iPhone, specializing in precision mold business including consumer electronics molds, optical molds, lens molds, medical device mold processing, etc., serving high-quality demanding customers such as Foxconn and Jabil Green Point.

The company strictly adheres to the ISO2015-9001 quality system and mold project management processes. The company uses an ERP management system, which allows for remote real-time control of the process. The company owns two Hexagon three-coordinate measuring machines, with a measurement precision of 1.3um/M. Every process undergoes precision testing, and all processes must meet Apple-level precision acceptance standards. The company selects the corresponding mold steel based on the customer's mold life requirements, with the high-precision plastic mold service life reaching over 500,000 to 1 million times.

We have been specializing in the research and development and production of human infrared sensor lenses, namely Fresnel lenses, and other products for more than a decade. The products are mainly used in industries such as security infrared alarms, lighting control infrared probes, human body sensor switches, and human body sensor lights.

Connecting your business with the world

A person can go fast, and a group of people will go further, cooperate sincerely, apply their strengths, and form an invincible and invincible strong team spirit

Quality objectives

Service policy

Management philosophy

Management idea

Enterprise mission

Our Services

Plastic Mold

CNC Machining

Fresnel Lens